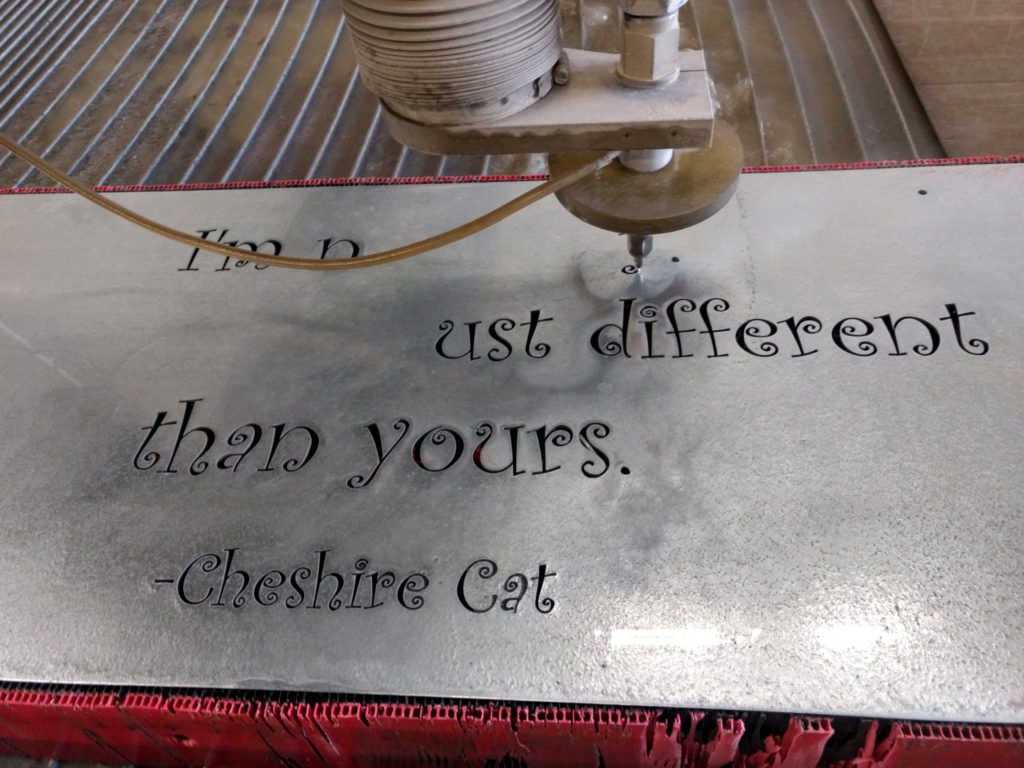

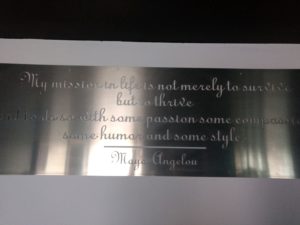

Waterjet Cutting Quality and Versatility for Crafting Personalized Projects

Waterjet cutting technology has revolutionized manufacturing and fabrication by providing unparalleled accuracy on various materials with minimal heat distortion. By combining high-pressure water and abrasive materials, this efficient process is not only fast but also safe— delivering outstanding precision to your projects quickly.

JFD Cutting is known for our top-notch waterjet cutting quality services within the manufacturing industry, but our offerings don’t stop there. We provide all the necessary tools and resources to help bring even your wildest ideas to life! Whether it’s a custom artwork or something with personal significance, JFD Cutting has you covered with our reliable, efficient service that guarantees your vision will turn into reality.

Unleash Your Creativity With Waterjet Cutting!

The unparalleled technology of waterjet cutting allows you to craft personalized projects and achieve fine results. Waterjet cutting has remarkable capabilities for intricate designs and complex shapes that necessitate exact cuts. No matter how ambitious your ideas are, there is a solution here for all your project needs. With its versatility and excellence in mind, it’s easy to understand why more people are investing in this form of precision cutting than ever before!

Why Use Waterjet Cutting On Your Custom Project?

Waterjet technology offers unmatched flexibility when it comes to design options. It can produce complex shapes with tight tolerances in cut materials ranging from stone and glass to plastic, rubber, wood, composites, aluminum alloys, and even titanium – no matter the material thicknesses! The process is incredibly accurate too; depending on the size of the part being cut, some machines have accuracy within 0.003 inches (0.076 mm). Waterjets offer superior edge quality with minimal burrs or debris left behind after each job is finished. And because there’s no contact between tooling and workpiece during operation, your project won’t suffer from wear and tear over time as other machining methods might experience.

How Does The Waterjet Cut Work On Your Personalized Projects?

The waterjet cut is a versatile and highly precise machining method that can be used on virtually any material, making it an ideal choice for custom fabrication projects. By using pressurized water mixed with an abrasive substance, waterjet cutting can achieve intricate shapes and patterns without causing heat-induced damage to the cut materials. This makes the waterjet cut perfect for parts that require fine details or are sensitive to high temperatures.

What Is The Difference Between Waterjet Cutting And Laser Cutting?

Laser cutting delivers precise, rapid cuts on a variety of materials with its concentrated laser beam. The benefits associated with employing laser technology include high accuracy slices, cutting speeds, and suitability for multiple types of material.

On the other hand, waterjet cutting, uses a pressurized liquid mixed with abrasive particles to cut through different elements. Waterjet cutting provides several benefits for your projects, including non-heat affected cuts, the ability to increase the cut speed capabilities for thicker materials than traditional methods allow, and no hazardous fumes or dust produced.

What Are More Advantages Of Using an Abrasive Waterjet Machine For Your Personalized Projects?

Waterjet technology offers efficient precision cutting with no associated heat-affected zones. So the abrasive waterjet is a versatile and efficient method for cutting various materials in personalized projects. Let’s explore some of these advantages:

Unparalleled precision

Waterjet cutting offers unparalleled precision; it can delicately cut even the hardest materials without causing damage, and thus results in minimal waste. With no need for additional processing steps, this process is highly efficient and cost-effective.

No material warping or cracking

The non-contact cutting process eliminates the risk of material warping or cracking, making it ideal for unique, one-of-a-kind projects. The ability to accurately cut complex shapes and patterns makes the abrasive waterjet cut a valuable option for personalized projects.

Versatility

The incredible versatility of the waterjet machine provides an unparalleled advantage, allowing you to effortlessly craft intricate designs tailored specifically for your project with superior results – be it delicate glass or hard metals. With its high precision cutting capabilities and convenient operation, waterjet technology is truly the perfect solution that lets you unleash your full creative potential!

Adjustable waterjet stream and reduced environmental impact

The high-pressure waterjet stream can be adjusted depending on the material being cut and the desired finish, allowing for a wide range of cutting possibilities. Waterjet cutting also offers an eco-friendly solution as it doesn’t require any additional materials or tools, making it an excellent option for anyone looking to reduce their environmental impact.

How Can We Help You Create The Perfect Finished Product?

We understand that not everyone has a background in design and cutting. That’s why JFD Cutting works closely with our customers to guide them through the process. We start by discussing their design ideas, creating a DXF cut file or CNC pattern, choosing the right materials and measurements necessary for accuracy, and scheduling any essential secondary processes to ensure a finished product that meets their expectations.

Bring Your Ideas To Life With Unique Personalized Cuts From JFD Cutting!

When you are ready to start a cutting project, you deserve to work with the experts with the experience and know-how to get your project done right the first time. JFD Cutting is committed to providing our customers superior customer service in everything from design to cutting and fabrication. With our extensive experience in the industry, we know what it takes to create accurate, beautiful cuts that meet our customers’ exact specifications.

We strive to ensure our customers get the highest satisfaction with their finished products. To do this, we take extra steps to ensure all measurements are precise and performed accurately, as well as carefully choose the right materials for each job. We also use state-of-the-art machinery, ensuring our cuts and fabrication are of the highest quality. Unleash your creativity and let JFD Cutting bring your ideas to life. Reach out now for more information or to get a quote for our remarkable services!