Discovering the Unrivaled Quality and Versatility of Waterjet Tile Cutting Projects

Waterjet cutting technology is revolutionizing the way we cut and design tiles. With its precise and efficient cutting capabilities, waterjet cutting is quickly becoming the go-to choice for tile cutting in the construction and architecture industry. In this article, we will explore the process and benefits of waterjet tile cutting, and showcase some of the best pictures of water’s power in JFD Cutting’s waterjet cutting projects.

Understanding Waterjet Tile Cutting

Waterjet tile cutting can produce intricate cuts and designs in hard surfaces such as steel, glass, and tiles by utilizing jets of pressurized water and abrasive waterjet materials like garnet or sand. The process requires a nozzle at the end of an ultra-high pressure hose that sprays powerful streams onto your desired material with precision, accuracy, and swiftness unmatched by any other technique available today. This high-pressure stream of water creates an exact and intricate design that traditional methods such as saws or drills cannot replicate. Waterjet cutting is also eco-friendly and sustainable, as it does not generate heat or produce harmful chemicals.

And the outcome is beautiful and resilient, making it perfect for all tiling projects! Whether it’s an intricate mosaic or a more complex pattern you’re looking for, this method of tile cutting proves to be extremely versatile, with no job too big or small. Professionals like interior designers, contractors, and DIYers can reap the benefits of this efficient cold-cutting process!

Advantages of Waterjet Tile Cutting Compared to Traditional Cutting Methods

The main advantages of using waterjets are their accuracy, efficiency, and precision compared to other methods. Waterjet technology is:

- More precise and accurate – resulting in fewer errors and a higher quality end product reduced material costs because less raw material needs to be purchased.

- More efficient – streamlining production cycles to cut down time and increase output while reducing the amount of energy consumed during each cycle.

- More versatile – allowing for the creation of intricate and complex designs that are difficult to achieve with traditional cutting methods.

- Eco-friendly – since fewer resources are needed during each production cycle. The water used for cutting can also be recycled, making this an excellent cutting option for businesses or manufacturers concerned about eco-friendliness.

Different Techniques Used to Create Decorative Tile Designs with Waterjet Cutters

Waterjet technology allows for the creation of intricate and complex tile designs. By etching, carving, or inlaying patterns into stone or marble pieces with a waterjet tile cutter, you can add an exquisite touch of sophistication to decorative tiles. Not only that, but this cutting-edge method also enables captivating mosaic designs with exacting detail and unique shapes for a truly one-of-a-kind look! The options are endless, with various methods available to bring your ideas to life! Waterjet cutting also offers a unique way of creating intricate 3D designs for an unforgettable and distinctive tiling installation.

Exploring Quality and Versatility with Water Jet Cutting Tile Projects

From intricate etchings carved in rock to awe-inspiring mosaic pieces crafted from porcelain tiles, there’s no limit to what can be accomplished when you use the incredible power of water jet-cutting tile technology! Not only is it versatile enough for decorative embellishments or breathtaking works of art, but its ability to work with any type of tile – porcelain, ceramics, natural stone, and glass – grants designers unmatched precision and flexibility. Water jet cutting makes creating one-of-a-kind projects truly possible!

Water Jet Cutter Process & Equipment

The actual process involved in tile cutting using a water jet cutter includes two main steps:

- Designing/Programming – Through CAD (Computer Aided Design) software, all desired shapes are programmed into the system before being directly transmitted to CNC (Computer Numerical Control) machines for actual cutting.

- Actual Cutting Process – By utilizing special nozzles on the waterjet cutting system, ultrahigh-pressure jets are precisely directed to the surface to create accurate and precise shapes that remain consistent over time without any deformation or inaccuracies from blade-based systems like saws or drills.

The types of waterjet cutting machines available range from basic to advanced, from small portable machines suitable for home DIY projects to industrial-scale machinery capable of mass-producing intricate designs on large surfaces with maximum efficiency and perfect symmetry. These powerful tools allow you to create beautiful objects quickly and precisely every time!

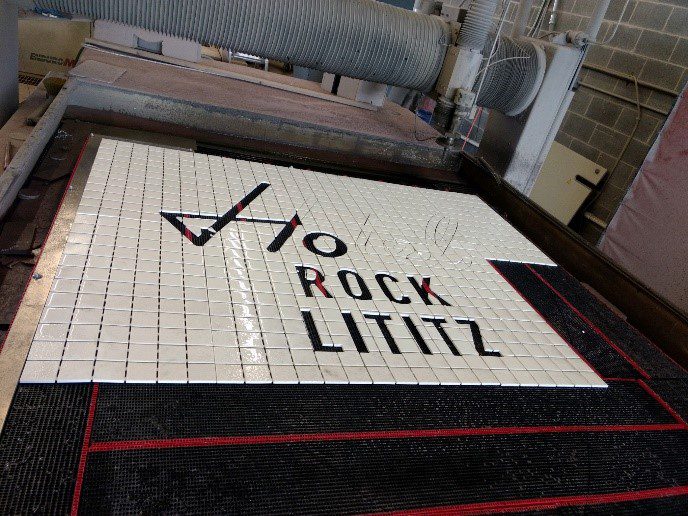

Showcasing Pictures of JFD Cutting’s Waterjet Cutting Tile Process

There are several items to pay close attention to when waterjet cutting tile: support, pierce, and pressure. Tile is a brittle material, so you need to take care during the entire job to minimize any breakage. First, the entire piece must be on the proper supportive material. Before the final cutting of the piece, you need to perform pressure tests to ensure the optimal pressure for that particular material.

The material in this piece, done for Martin’s Flooring, was a ¼”X 2” X 2” porcelain tile with a mesh backing 12” X 24”. This tile was supported by a waterjet brick bed which provided an ideal cutting surface. Several test cuts were done before cutting the piece, allowing Nick to select the optimal cutting pressure. It was then pierced and cut at 18000 psi, a deviation from our standard 60,000 psi, to ensure no chipping during the final cut.

Learn More About JFD Cutting’s Waterjet Cutting Tile Process

JFD Cutting can cut any shape or size of tile you need for your project accurately and precisely. Our process leaves a smooth edge finish on the tiles, which reduces any need for additional finishing processes.

At JFD Cutting, we strive to provide the highest quality water jet tile cutting services and products possible. Our experienced team is dedicated to providing you with a reliable and professional waterjet cutting tile process that will meet all of your needs. We use only the best materials to ensure your tile pieces are of premium quality and will last a lifetime. Contact us today to learn more about our waterjet cutting tile process and how we can help with your project.